Dengan munculnya limbah plastik dalam skala besar, daur ulang plastik telah menjadi isu penting di bidang perlindungan lingkungan. Untuk memproses dan menggunakan kembali limbah plastik secara efektif, berbagai peralatan daur ulang plastik telah muncul. Dalam makalah ini, kami akan memperkenalkan empat jenis peralatan daur ulang plastik yang berbeda, termasuk penghancur, peralatan pencucian, peralatan pengeringan, dan granulator.

Mesin penghancur plastik

Pentingnya mesin penghancur plastik sebagai proses pertama dari peralatan daur ulang plastik tidak dapat diabaikan. Produk plastik yang dibuang biasanya besar dan tidak mendukung penyimpanan serta transportasi. Mesin penghancur plastik mampu mengubah produk plastik besar ini menjadi potongan kecil yang mudah dikelola, menciptakan kondisi untuk tahap pemrosesan selanjutnya. Setelah produk plastik limbah dihancurkan, luas permukaan meningkat, yang memfasilitasi pemrosesan dan penyortiran yang lebih efisien oleh peralatan lainnya.

mesin pencuci plastik

Peralatan pencucian memainkan peran penting dalam peralatan daur ulang plastik. Produk plastik limbah sering digunakan dalam jangka waktu tertentu dan mungkin memiliki kotoran dan minyak yang menempel pada permukaannya. Setelah dipotong menjadi potongan kecil atau "serpihan" oleh mesin penghancur plastik, sering kali perlu untuk mencuci material dalam mesin pencuci untuk menghilangkan kotoran atau adhesi yang tersisa.

Ini karena kontaminan ini tidak hanya mempengaruhi kualitas plastik daur ulang tetapi juga dapat mempengaruhi pemrosesan dan penggunaan selanjutnya, mengurangi kegunaannya. Pembersih dan disinfektan sering ditambahkan ke proses ini untuk meningkatkan kebersihan.

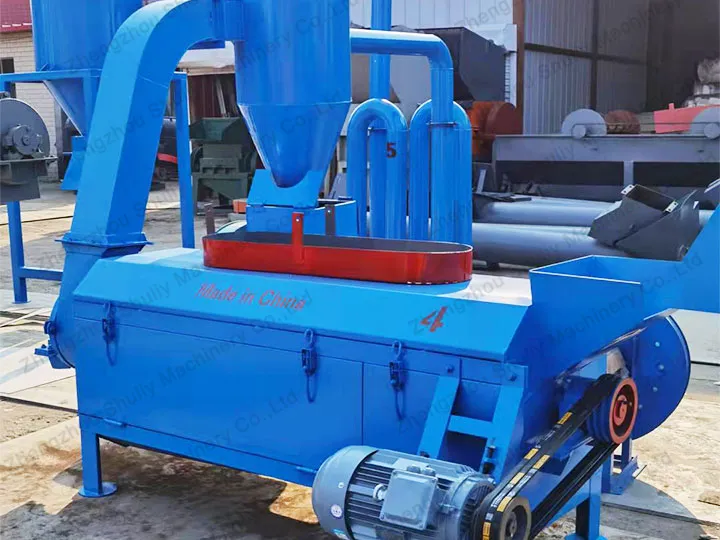

Mesin pengering plastik

Peralatan pengeringan memainkan peran kunci dalam peralatan daur ulang plastik. Kelembapan dapat berdampak negatif pada pemrosesan ulang dan peletisasi plastik. Peralatan pengeringan digunakan untuk mengeringkan butiran plastik yang telah dibersihkan.

Selama proses pencucian, butiran plastik menyerap sejumlah air, yang, jika tidak dihilangkan, dapat mempengaruhi proses peletisasi selanjutnya. Dengan peralatan pengering, kelembapan dapat dihilangkan secara efektif untuk memastikan bahwa pelet plastik mempertahankan sifat fisik yang baik selama pemrosesan selanjutnya.

mesin pelet plastik

Peletisasi plastik daur ulang adalah langkah terakhir dalam sebagian besar proses daur ulang. Mengubah plastik pasca-konsumen menjadi pelet memungkinkan distribusi dan pembuatan ulang yang lebih mudah, dan pada akhirnya memfasilitasi kecepatan dan efektivitas pengenalan kembali plastik daur ulang ke dalam manufaktur industri.

Pelet plastik yang telah dihancurkan, dicuci, dan dikeringkan dipanaskan dan diekstrusi menjadi bahan granular yang seragam. Pelet ini kemudian dapat digunakan untuk memproduksi produk plastik baru seperti lembaran plastik, pipa, wadah, dan sebagainya.

Peralatan daur ulang plastik Shuliy dijual

Sebagai produsen terkemuka di bidang peralatan daur ulang plastik, Shuliy berkomitmen untuk pengembangan dan produksi peralatan daur ulang plastik yang efisien dan hemat energi. Produk perusahaan mencakup berbagai macam penghancur, peralatan pencucian, peralatan pengeringan, dan granulator. Kerajinan yang sangat baik dan teknologi canggih memastikan stabilitas dan keandalan peralatan serta secara signifikan meningkatkan efisiensi daur ulang plastik.

Peralatan Shuliy dapat memenuhi berbagai kebutuhan dan dapat disesuaikan sesuai dengan permintaan pelanggan. Jika Anda tertarik dengan peralatan daur ulang plastik kami, silakan hubungi kami melalui pesan di situs web atau telepon!