Mesin pengering plastik adalah sejenis peralatan yang digunakan untuk menghilangkan air dari permukaan plastik selama daur ulang dan pengolahan plastik. Fungsi utamanya adalah untuk secara efektif menghilangkan air dari serpihan plastik, film, atau butiran yang telah dibersihkan dengan rotasi kecepatan tinggi atau metode pengeringan lainnya, memastikan bahwa bahan plastik tetap kering saat memasuki langkah pengolahan berikutnya.

Ini meningkatkan kualitas pemrosesan dan produktivitas bahan plastik sambil mengurangi konsumsi energi dan keausan peralatan. Mesin pengeringan plastik banyak digunakan di berbagai lini daur ulang plastik, seperti lini daur ulang botol PET, pabrik pencucian daur ulang plastik, dll. Mereka cocok untuk berbagai jenis bahan plastik.

Prinsip Kerja Mesin Pengering Plastik

Prinsip kerja mesin pengering plastik terutama didasarkan pada prinsip gaya sentrifugal. Material masuk ke dalam mesin pengering melalui saluran masuk, dan di bawah pengaruh gaya sentrifugal dari putaran kecepatan tinggi, air dalam plastik dengan cepat dilempar keluar. Proses spesifiknya adalah sebagai berikut:

- Pakan: Serpihan plastik, film, atau butiran yang telah dibersihkan masuk ke dalam dehidrator melalui lubang pakan.

- Rotasi kecepatan tinggi: Poros yang berputar di dalam pengering sentrifugal berputar dengan kecepatan tinggi, menghasilkan gaya sentrifugal yang kuat.

- Pembuangan kelembapan: di bawah pengaruh gaya sentrifugal, kelembapan di permukaan plastik dengan cepat dibuang dan dikeluarkan dari mesin melalui saluran pembuangan.

- Proses pengeringan: Plastik yang telah didehidrasi dibuang melalui port pembuangan dan masuk ke langkah pemrosesan berikutnya.

Mesin pengering plastik kami mengadopsi prinsip gaya sentrifugal yang canggih untuk memastikan efek pengeringan yang efisien. Pada saat yang sama, peralatan ini memiliki struktur yang kompak, mudah dioperasikan, dan cocok untuk berbagai jenis bahan plastik, yang dapat memenuhi kebutuhan berbagai pelanggan.

Aplikasi Mesin Pengering Sentrifugal

Mesin pengering plastik banyak digunakan dalam proses penghilangan air dari berbagai bahan plastik, seperti PET, PVC, PP, PE, dan sebagainya. Dalam berbagai jalur pencucian, sesuai dengan jenis bahan dan kebutuhan produksi, memilih dehidrator yang tepat dapat secara signifikan meningkatkan efisiensi kerja dan kualitas produk.

Pengering Horizontal

Aplikasi: Pengering horizontal biasanya digunakan dalam jalur pencucian botol PET dan jalur pencucian untuk PVC, HDPE, dan plastik keras lainnya.

Peran: Dalam jalur pencucian plastik ini, pengering horizontal secara efektif menghilangkan kelembaban dari permukaan plastik melalui rotasi berkecepatan tinggi dan gaya sentrifugal yang kuat, memastikan kekeringan bahan selama proses pemrosesan selanjutnya.

Pengering Vertikal

Aplikasi: Pengering vertikal terutama digunakan dalam jalur pencucian film plastik.

Fungsi: Pengering vertikal biasanya dipasang setelah tangki pencucian untuk mengekstrak film plastik dari tangki pencucian dan mengeringkannya. Strukturnya dirancang untuk menangani film plastik ringan dan menghindari penyumbatan film selama proses pengeringan.

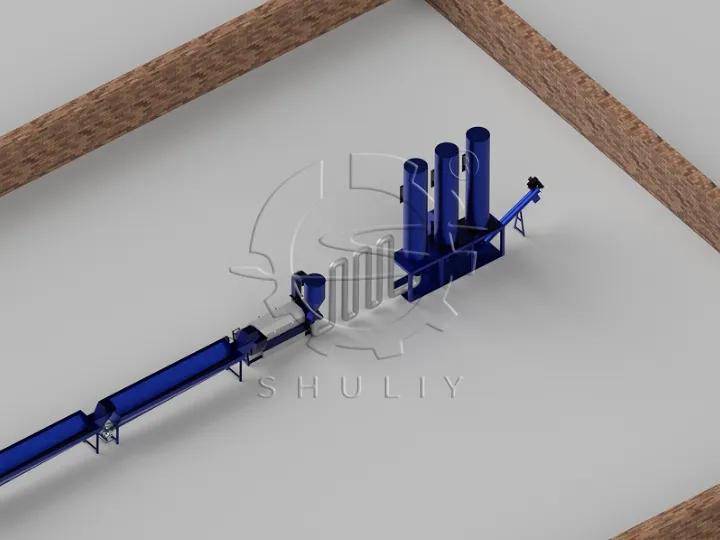

Penggunaan Gabungan

Untuk mencapai tingkat kekeringan yang lebih tinggi, pelanggan dapat memilih untuk menggunakan pengering vertikal bersamaan dengan pengering horizontal. Pengering vertikal akan terlebih dahulu melakukan perlakuan pengeringan awal, dan kemudian pengering horizontal akan melakukan pengeringan mendalam untuk memastikan bahwa kekeringan produk akhir memenuhi persyaratan produksi.

Keuntungan Mesin Pengering Plastik

Kinerja Pengeringan yang Sangat Efisien

Mesin pengering horizontal kami mampu mengeringkan lembaran plastik hingga 95%-98%, memberikan hasil pengeringan yang sangat baik. Untuk pelanggan dengan kebutuhan kekeringan yang lebih tinggi, kami juga menawarkan pipa pengering yang dapat mengontrol kelembapan pada kurang dari atau sama dengan 0,5%-1%. Pipa pengering terbuat dari stainless steel 304 untuk memastikan daya tahan dan kebersihan.

Desain Keamanan

Mesin pengering plastik kami dirancang dengan pembuangan siklon, yang fungsi utamanya adalah memperlambat dan mencegah bahan yang tumpah melukai pekerja. Desain ini secara signifikan meningkatkan keselamatan peralatan dan melindungi operator.

Ragam Aplikasi yang Luas

Mesin pengering plastik memiliki berbagai aplikasi dan dapat memenuhi kebutuhan pelanggan dalam menangani berbagai jenis bahan plastik, termasuk PET, PVC, PP, PE, dan sebagainya. Baik itu plastik kaku atau film plastik, peralatan kami dapat menangani dengan efisien dan memberikan hasil pengeringan terbaik.

Parameter Teknis Pengering Plastik

Mesin pengering horizontal kami dirancang untuk pengeringan bahan plastik yang efisien dan berikut adalah parameter utama dari peralatan ini:

- Tingkat pengeringan: 95%-98%, cocok untuk sebagian besar kebutuhan pengeringan lembaran plastik.

- Pipa pengering: terbuat dari stainless steel 304 untuk memastikan daya tahan dan kebersihan, dapat mengontrol kelembapan pada 0,5%-1%.

- Kapasitas pemrosesan: hingga 1.000 kilogram material plastik per jam, cocok untuk produksi massal.

- Daya motor: dukungan motor yang kuat, tegangan 380V, 50HZ, daya 3 fase, daya 15kw.

- Ketebalan dinding luar 4mm, ketebalan bilah 10mm.

- Ruang lingkup aplikasi: banyak digunakan dalam bahan plastik PET, PVC, PP, PE, dan lainnya.

Kasus Perdagangan Sukses dari Pengering Material Plastik

Mesin Pengering Plastik Dikirim Ke Nigeria

Seorang pelanggan di Nigeria telah membeli satu set lengkap mesin daur ulang botol PET, termasuk mesin pengering plastik, yang diikuti dengan pemisah udara. Mesin pengering plastik untuk mengeringkan lembaran plastik hingga 95%-98%, pemisah udara untuk menghilangkan sisa label halus dan debu. Pabrik daur ulang botol plastik kami akan membantunya untuk mendaur ulang dan membuang botol plastik dengan lebih efisien dan dengan demikian menghasilkan keuntungan darinya.

Mesin Pengering Film Plastik Dikirim Ke Indonesia

Pelanggan dari Indonesia, yang berada dalam bisnis daur ulang plastik dan memiliki pabrik daur ulang plastik sendiri, membutuhkan pabrik pencucian dan pengeringan untuk memproses fragmen film plastik dengan ukuran bahan baku sekitar 1cm dan ingin menghilangkan air dari bahan hingga tingkat kelembaban kurang dari 0,5%.

Kami menyesuaikan solusi sesuai dengan kebutuhan pelanggan. Ukuran layar mesin pengering plastik disesuaikan dengan ukuran bahan baku pelanggan dan dilengkapi dengan pipa pengering untuk memastikan bahwa tingkat kekeringan memenuhi persyaratan pelanggan.

Mesin Pengering Limbah Plastik Shuliy Dijual

Bagaimana cara membeli mesin pengering daur ulang plastik yang paling sesuai untuk pabrik Anda? Pertama-tama, Anda perlu memilih model yang tepat sesuai dengan skala produksi dan permintaan Anda. Kedua, mempertimbangkan efisiensi produksi dan konsumsi energi, memilih mesin pengering plastik Shuliy bisa menjadi pilihan yang bijak.

Selain itu, untuk memenuhi kebutuhan berbagai pelanggan, Shuliy menawarkan berbagai model dan opsi kustomisasi untuk memastikan bahwa setiap jalur produksi dapat menemukan solusi pengeringan yang paling sesuai. Ketika Anda memilih mesin pengering flake plastik Shuliy, Anda mendapatkan alat pengering yang efisien dan dapat diandalkan untuk produksi plastik Anda. Jika Anda tertarik dengan pengering plastik atau memiliki pertanyaan, Anda dapat menghubungi kami kapan saja, akan ada staf profesional yang siap menjawab Anda dengan hati-hati.

Permintaan untuk Mesin Pengering Plastik!

Ingin pengering plastik yang efisien untuk meningkatkan efisiensi daur ulang plastik? Jika Anda tertarik dengan peralatan daur ulang plastik ini dan ingin mengetahui lebih banyak detail, saya sarankan Anda menghubungi kami langsung untuk solusi yang disesuaikan. Kami adalah produsen peralatan daur ulang plastik profesional dan dapat memberikan informasi terperinci tentang mesin daur ulang botol plastik dan peralatan daur ulang plastik lainnya, serta menawarkan saran dan dukungan profesional kepada Anda.