Mesin pengering plastik adalah peralatan yang sangat penting dalam produksi industri modern, yang digunakan untuk mengeringkan air dari produk plastik secara menyeluruh dalam proses produksi, untuk meningkatkan kualitas produk dan efisiensi produksi. Di pasaran, mesin pengering plastik yang umum dibagi menjadi dua jenis utama: mesin pengering tipe vertikal dan mesin pengering tipe horizontal. Dalam artikel ini, kami akan memperkenalkan dan membandingkan kedua jenis ini secara rinci, dan pada saat yang sama, memberikan Anda panduan praktis untuk membeli mesin pengering plastik.

mesin pengering tipe vertikal

Mesin pemisah air tipe vertikal adalah jenis peralatan untuk menghilangkan air dengan gaya sentrifugal dalam proses rotasi berkecepatan tinggi dengan menempatkan produk plastik dalam drum vertikal. Mesin ini memiliki karakteristik sebagai berikut:

- Kapasitas pengeringan yang efisien: Desain drum vertikal dari mesin pengering tipe vertikal dapat memaksimalkan penggunaan gaya sentrifugal, sehingga dapat mengeringkan produk plastik dengan cepat dalam waktu singkat.

- Penghematan energi dan perlindungan lingkungan: Karena waktu pengeringan yang singkat, konsumsi energi relatif rendah, yang membantu mengurangi biaya produksi dan dampak lingkungan.

- Ruang lingkup aplikasi yang luas: Pengering vertikal plastik cocok untuk produksi produk plastik berskala kecil hingga menengah, seperti film plastik, dll.

- Mudah dioperasikan: Relatif sederhana untuk digunakan, tanpa perlu keterampilan operasional yang kompleks.

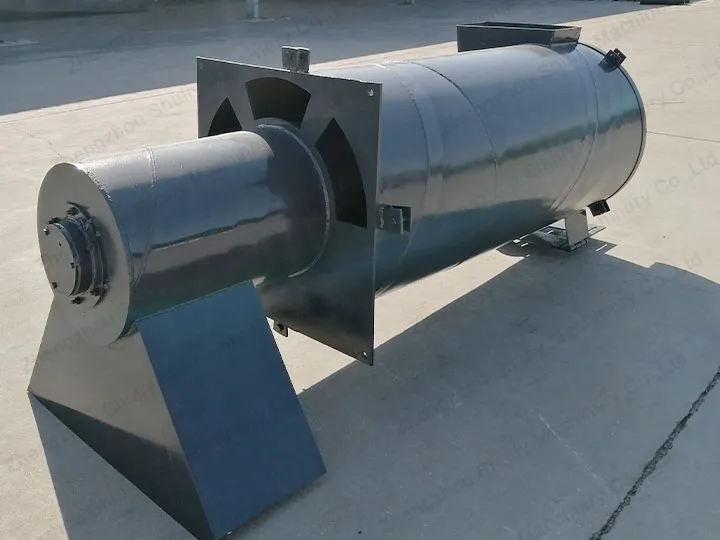

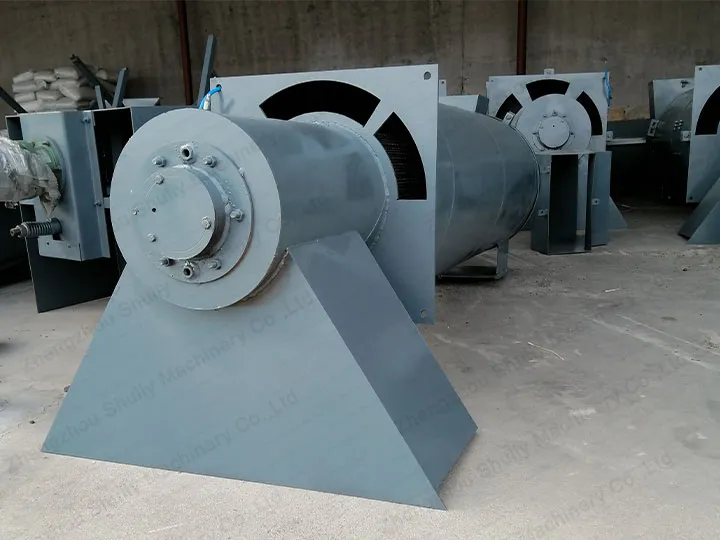

Mesin pengering horizontal

Mesin pemisah air horizontal menghilangkan air dari produk plastik dengan memutarnya dalam drum berputar horizontal. Fitur-fiturnya adalah sebagai berikut:

- Efek pengeringan yang merata: Dengan berputar secara horizontal, mesin pengering dewatering horizontal dapat mencapai efek pengeringan yang lebih merata, yang cocok untuk beberapa produk plastik yang memerlukan efek pengeringan yang tinggi.

- Kapasitas lebih besar: Karena desain horizontalnya, pengering horizontal biasanya cocok untuk mengeringkan jumlah besar produk plastik.

- Beragam aplikasi: Pengering horizontal cocok untuk berbagai produk plastik dengan spesifikasi dan ukuran yang berbeda, termasuk ukuran besar botol plastik dan drum.

- Optimisasi Proses: Untuk produk plastik tertentu yang memerlukan kontrol proses yang halus, pengering horizontal dapat memberikan lebih banyak ruang operasi dan penyesuaian parameter.

Pemilihan dan penerapan mesin pengering plastik

Memilih mesin pengering plastik yang tepat sangat penting untuk produksi produk plastik. Berikut adalah beberapa pertimbangan:

- Persyaratan produksi: Jika Anda perlu mengeringkan sejumlah besar produk plastik, mesin pengering horizontal mungkin lebih cocok. Untuk batch kecil, pengering vertikal mungkin lebih ekonomis.

- Efektivitas: Jika Anda memerlukan tingkat efektivitas yang lebih tinggi, pengering horizontal mungkin lebih cocok, tetapi juga dapat meningkatkan biaya.

- Kontrol proses: Jika Anda memerlukan kontrol proses yang lebih halus, pengering horizontal mungkin menawarkan lebih banyak opsi penyesuaian.

- Keterbatasan ruang: Mengingat keterbatasan ruang di lokasi produksi Anda, penting untuk memilih ukuran mesin pengering plastik yang tepat.