El extrusor de pelletizado de plástico se utiliza para calentar, comprimir y derretir plásticos de desecho y luego pasarlos a través de la cabeza del extrusor para darles forma en pellets de plástico. Sin embargo, a veces el proceso de producción puede encontrar el problema de la rotura de tiras de plástico, lo que afecta la eficiencia de producción y la calidad del producto. En este artículo, discutiremos las causas de las tiras rotas en la máquina de granulación de PE y proporcionaremos las contramedidas correspondientes.

Causas del problema de tiras rotas en el extrusor de peletizado de plástico

- Control de temperatura inadecuado: Extrusora de pelletizado de plástico se requiere un control preciso de la temperatura de calentamiento para asegurar que el plástico se pueda derretir completamente y extruirse de manera suave. Si la temperatura no se establece correctamente, el plástico no se derretirá lo suficiente, lo que resultará en barras rotas.

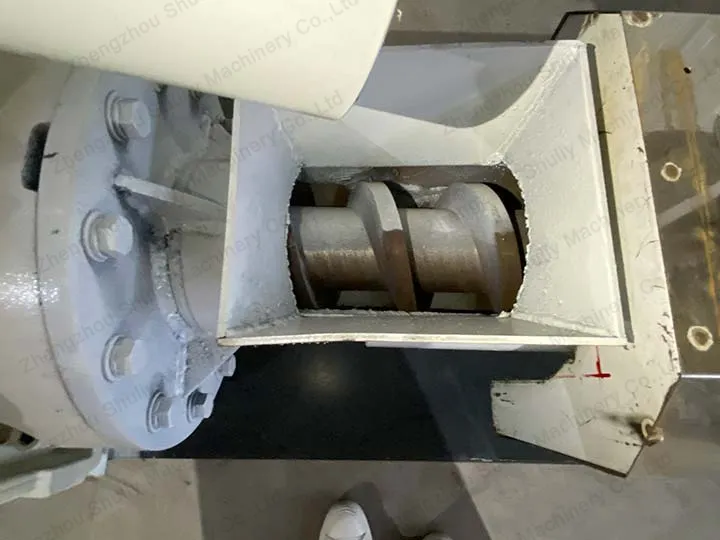

- Problemas con la cabeza del extrusor: La cabeza del extrusor es uno de los componentes más críticos en un extrusor de pelletizado de plástico. Si la cabeza no está bien diseñada o está dañada, provocará fácilmente que la tira de plástico se rompa.

- La presión de extrusión es demasiado alta o demasiado baja: El tornillo de extrusión dentro del extrusor de pelletizado de plástico ejerce una cierta presión para empujar el plástico hacia adelante y formar pellets a través de la salida de extrusión. La presión de extrusión del extrusor de pelletizado de plástico debe ajustarse adecuadamente, demasiado grande o demasiado pequeña puede llevar a la inestabilidad de las partículas de plástico, y luego al fenómeno de tiras rotas.

- Temperatura anormal del agua de enfriamiento: Después de la extrusión, el plástico necesita ser enfriado rápidamente con agua de enfriamiento para solidificarse en pellets. Si la temperatura del agua de enfriamiento es anormal o el suministro de agua es inestable, causará pellets de plástico desiguales o rotos.

- Tornillos desgastados: La operación prolongada y los entornos de alta temperatura pueden causar desgaste en los tornillos de la máquina de granulación de PE, reduciendo su eficiencia de extrusión. Un tornillo desgastado puede no ser capaz de empujar el plástico de manera eficiente, haciendo que el plástico se rompa en tiras.

Soluciones para tiras rotas en el extrusor de peletizado de plástico

- Controlar la temperatura con precisión: Verifique regularmente el sistema de calefacción de la máquina para hacer pellets de plástico, asegúrese de la precisión del sensor de temperatura, ajuste la temperatura al rango apropiado y evite que una temperatura demasiado alta o demasiado baja cause tiras rotas.

- Verifique la cabeza del extrusor: Revise regularmente el desgaste de la cabeza del extrusor, reemplácela a tiempo si se encuentra alguna anomalía y asegúrese de que la cabeza esté bien diseñada para evitar que los gránulos de plástico se bloqueen en el proceso de extrusión.

- Ajuste la presión de extrusión adecuadamente: Ajuste la presión de extrusión del extrusor de acuerdo con las características del plástico y la situación de producción para garantizar la extrusión estable de gránulos de plástico.

- Optimizar el sistema de refrigeración: Asegúrese de que la temperatura del agua de refrigeración sea estable y que el flujo de agua sea suficiente, ajuste el sistema de refrigeración adecuadamente para garantizar que los gránulos de plástico se enfríen y curen rápidamente para prevenir el problema de las barras rotas.

- Revisar y reemplazar regularmente el tornillo: Revise regularmente el grado de desgaste del tornillo y reemplace el tornillo con desgaste serio a tiempo para garantizar la eficiencia de extrusión y la calidad del producto. Además, elegir tornillos de buena calidad también es una medida efectiva para prevenir el desgaste del tornillo.

Granulador de plástico Shuliy en venta

Shuliy es un fabricante profesional de extrusoras de peletización de plástico. Su máquina para fabricar pellets de plástico se fabrica utilizando tecnología avanzada y materiales de alta calidad para evitar el problema de rotura de las tiras. Los pellets de plástico producidos son de excelente calidad y satisfacen las necesidades de los clientes.

Si está interesado, no dude en contactarnos para obtener información más detallada sobre el precio de la máquina peletizadora de plástico, los parámetros y otros detalles de la máquina peletizadora de plástico.