خزان شطف البلاستيك الخاص بنا عبارة عن معدات عالية الكفاءة مصممة لإعادة تدوير البلاستيك وغسله، والتي تستخدم بشكل أساسي لإزالة الشوائب والأوساخ من سطح البلاستيك. المعدات مصنوعة من الفولاذ المقاوم للصدأ، وهو قوي ولديه مقاومة ممتازة للتآكل. إنها مناسبة لتنظيف جميع أنواع النفايات البلاستيكية، بما في ذلك جميع أنواع الرقائق الصلبة PP PE PVC أو شظايا الأفلام.

مقدمة لغسالة البلاستيك

تعتبر غسالة الرقائق البلاستيكية قطعة رئيسية من المعدات الموجودة خلف كسارة البلاستيك، والذي يستخدم لمعالجة البلاستيك المسحوق.

يسقط البلاستيك المسحوق مباشرة في خزان الغسيل، ويمكن لأسطوانات التحريك المتعددة في الخزان أن تحرك المواد بشكل فعال، وتنظف الشوائب والأوساخ على سطح البلاستيك، وفي نفس الوقت تجبر المادة على التحرك للأمام.

في نهاية خزان الغسيل، عادة ما يتم توصيل آلة نزح المياه العمودية، والتي تستخدم لرفع المواد وإجراء التجفيف الأولي. لا تقوم غسالة البلاستيك بإزالة الملوثات بكفاءة من سطح البلاستيك فحسب، بل تتصل أيضًا بسلاسة بآلة نزح المياه لتحسين كفاءة عملية الغسيل ونزح المياه بأكملها. يضمن هذا المزيج أن يكون البلاستيك المغسول نظيفًا وخاليًا من الملوثات، مما يوفر مادة خام عالية الجودة لإعادة التدوير والمعالجة اللاحقة.

مزايا غسالة نفايات البلاستيك

مواد ذات جودة عالية: خزان التنظيف مصنوع من الفولاذ المقاوم للصدأ المقاوم للتآكل، مما يضمن عدم الصدأ لفترة طويلة كما أنه سهل التنظيف والصيانة.

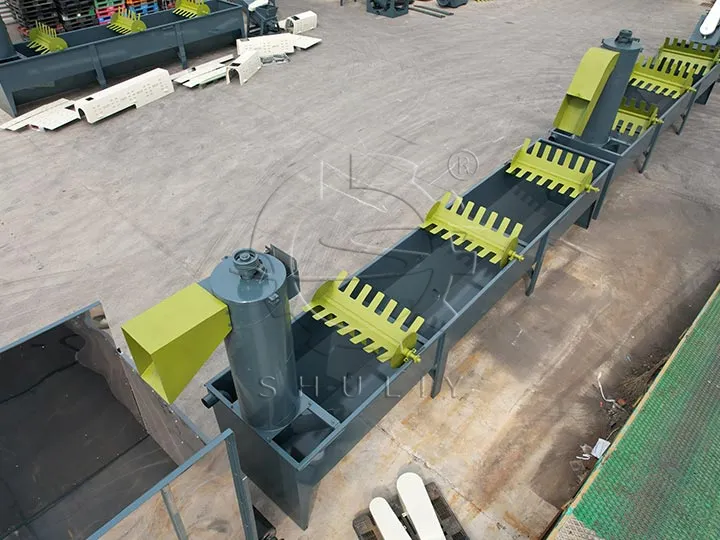

نظام التحريض عالي الكفاءة: يتم تجهيز خزان الغسيل عادةً بثلاثة صفوف من عجلات التحريك، والتي تعمل بشكل فعال على إزالة الشوائب والأوساخ من السطح البلاستيكي من خلال التقليب القوي. وفقاً لطلب الإنتاج الخاص بالعميل ودرجة المواد الخام المتسخة، يمكننا تمديد طول خزان الغسيل أو تكوين خزانين للتنظيف لتحسين تأثير التنظيف.

التخصيص المرن: لتلبية احتياجات العملاء المختلفين، يمكن تعديل طول غسالة النفايات البلاستيكية وعدد عجلات التحريك وفقًا للحالة المحددة، لتحسين تأثير التنظيف.

توافق مثالي للمجففات الرأسية: غالبًا ما يتم توصيل غسالات النفايات البلاستيكية مجففات عمودية في النهاية، والتي يمكنها رفع المواد البلاستيكية المغسولة وإجراء عملية التجفيف الأولي. ومن خلال هذا المزيج، يتم دمج عملية الغسيل ونزح المياه بسلاسة، مما يزيد من كفاءة عملية إعادة التدوير والتخلص بأكملها.

هيكل خزان الغسيل البلاستيكي

عادةً ما تكون خزانات الشطف البلاستيكية مصنوعة من مواد بلاستيكية عالية القوة ومقاومة للتآكل لضمان التشغيل المستقر على المدى الطويل. هيكلها الرئيسي يشتمل على جسم الخزان، مدخل المياه، الصرف، وجهاز الخلط.

يعتمد جسم الخزان تصميمًا عميقًا وواسعًا لاستيعاب عدد كبير من المنتجات البلاستيكية، بينما يقع مدخل المياه وصرفها في مواقع مناسبة لضمان التوزيع المتساوي لتدفق المياه والتفريغ الفعال. يستخدم جهاز الخلط عادةً لوحة مسننة أو تحريك تدفق الماء، والذي يستخدم لخلط سائل التنظيف بشكل كافٍ أثناء عملية التنظيف لتحسين تأثير التنظيف. من خلال التصميم الهيكلي المعقول، يمكن لخزان شطف البلاستيك إزالة الملوثات السطحية بشكل فعال وإنشاء ظروف جيدة لعملية إعادة تدوير البلاستيك اللاحقة.

مبدأ العمل لغسالة إعادة تدوير البلاستيك

يتم وضع المادة في الجزء الأمامي من غسالة إعادة تدوير البلاستيك، وتدور عجلة تبديل الشطف وتدفع المادة للشطف والتحرك للأمام، ويتم ترسيب الغنائم والشوائب الموجودة على المادة إلى الأسفل أثناء عملية الشطف.

بعد عدة شطف لعجلة المجداف، تصل المادة إلى نهاية الحوض، ومن ثم تخرج شوكة التفريغ من الحوض. يحتوي الجزء السفلي من الحوض على ثلاثة منافذ للصرف الصحي، عندما تتراكم الفسدة والشوائب بشكل أكبر، يمكن تفريغ الفسدة والشوائب عن طريق منفذ الصرف الصحي.

معلمات غسالة الرقائق البلاستيكية

الموديل SL-150 هو خزان غسيل بلاستيكي موديل قياسي مصمم لأطوال تتراوح بين 15 و 20 مترًا، مزود بـ 6-10 عجلات دوارة بمسافة بين كل عجلتين تتراوح بين 1.5 و 2 متر. انها مناسبة ل مصانع تكوير البلاستيك مع مخرجات في حدود 100-500 كجم/ساعة. يبلغ طول أقصر خزان غسيل لدينا 5 أمتار مزودًا بعجلتين للتحريك للحصول على مخرجات أصغر.

ومع ذلك، بمجرد زيادة إنتاجك تدريجيًا إلى مستوى 600-1000 كجم/ساعة، لضمان قدرتك على التعامل بكفاءة مع عمليات إنتاج أكبر، توصي Shuliy بأن تفكر في الترقية إلى خزان شطف بلاستيكي أطول، مثل الطراز الذي يبلغ طوله ثلاثين مترًا. من خلال اختيار آلة ذات سعة أكبر، يمكنك التأكد من أنه يمكنك الحفاظ على عملية فعالة بمعدلات إنتاج عالية وتلبية احتياجات الإنتاج المتزايدة لديك. يمكنك أيضًا عدم التردد في الاتصال بنا للحصول على حلول متخصصة.

عرض مصنع خزان الشطف البلاستيكي

إذا كنت مهتمًا بخزان شطف البلاستيك أو معدات إعادة تدوير البلاستيك الأخرى، فيرجى الاتصال بنا لمناقشة تفاصيل الأسعار والطلب في أي وقت.

سعر غسالات البلاستيك

نحن نقدم خزانات الشطف البلاستيكية عالية الجودة والمتينة وبأسعار معقولة وتنافسية. تم تصميم غسالات البلاستيك لدينا بشكل جيد مع تكنولوجيا التصنيع المتقدمة لضمان الاستقرار والكفاءة. سواء كنت بحاجة إلى ترقية المعدات الخاصة بك أو إعداد جهاز جديد مصنع تكوير البلاستيك، سوف تلبي غسالات الأفلام البلاستيكية لدينا احتياجاتك. لا تتردد في الاتصال بنا، وسوف نقدم لك معلومات مفصلة حول سعر خزان الشطف وتخصيص الحل الأنسب لك.