HDPE mashine ya kusambaza pelletizing ina jukumu muhimu katika kuchakata na kuchakata plastiki. Hata hivyo, wakati mwingine kunaweza kuwa na hali ambapo pelletizer ya plastiki haitoi nyenzo, ambayo inathiri sana ufanisi wa uzalishaji. Makala hii itachambua sababu zinazowezekana za tatizo hili na kutoa ufumbuzi.

Kuziba husababisha mashine ya kusambaza pelletizing ya HDPE si kutoa nyenzo

Kuziba ni moja ya sababu kuu kwa nini mashine ya HDPE ya pelletizing haitoi nyenzo. Plastiki inaweza kusababisha kuziba wakati wa usindikaji kutokana na mkusanyiko wa uchafu, joto lisilofaa na mambo mengine.

Ufumbuzi

- Usafishaji wa mara kwa mara: Hakikisha kuwa sehemu ya ndani ya mashine ya kusagia HDPE inasafishwa mara kwa mara ili kuzuia mrundikano wa uchafu. Hii husaidia kudumisha mtiririko mzuri wa nyenzo.

- Joto linalofaa: Dhibiti halijoto ya uchakataji ili kuepuka joto kupita kiasi na kunata kwa plastiki. Joto sahihi litasaidia kuondoa matatizo ya kuziba.

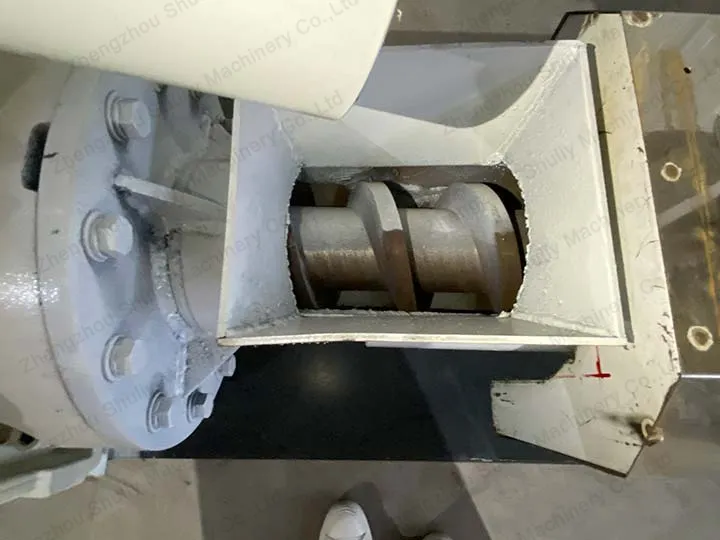

Kushindwa kwa screw

Parafujo ni sehemu ya msingi ya granulator kuchakata plastiki, uharibifu screw au jam itasababisha nyenzo haiwezi kuruhusiwa kawaida.

Ufumbuzi

- Angalia skrubu mara kwa mara: Weka mfumo wa ukaguzi wa mara kwa mara ili kuhakikisha kwamba skrubu haijashikanishwa na vitu vya kigeni au kuharibiwa. Gundua shida na ushughulikie kwa wakati.

- Tumia skrubu ya ubora wa juu: Chagua skrubu ya ubora wa juu, inayostahimili kuvaa, inayostahimili kutu, boresha uthabiti wa kifaa.

Mpangilio usiofaa wa vigezo vya uendeshaji

Mipangilio isiyo sahihi ya vigezo vinavyoendesha inaweza kusababisha granuta ya kuchakata tena plastiki kutotoa nyenzo, kama vile kasi ya kulisha, kasi ya kuzunguka, n.k.

Ufumbuzi

- Vigezo vya busara vya kuweka: Kulingana na aina ya mahitaji ya plastiki na usindikaji, weka kasi ya malisho, kasi ya mzunguko na vigezo vingine kwa njia inayofaa ili kuhakikisha kuwa operesheni imesawazishwa.

- Marekebisho ya mtihani: Matumizi ya kwanza au nyenzo za kubadili, marekebisho ya mtihani ili kupata mchanganyiko unaofaa zaidi wa vigezo.

Kushindwa kwa mfumo wa udhibiti wa kielektroniki

Kushindwa kwa mfumo wa udhibiti wa kielektroniki kunaweza kusababisha mashine ya kusambaza pelletizing ya HDPE kuacha kufanya kazi, na hivyo kusababisha nyenzo zishindwe kutolewa kwa kawaida.

Ufumbuzi

- Angalia mara kwa mara mfumo wa udhibiti wa umeme: Angalia waya, vituo na sehemu nyingine ili kuhakikisha kwamba uhusiano wa umeme ni mzuri, ili kuepuka matatizo ya umeme yanayosababishwa na kushindwa kwa vifaa.

- Hifadhi rudufu ya nishati: Masharti yakiruhusu, usambazaji wa nishati mbadala unaweza kuhakikisha kuwa mashine ya HDPE ya kuweka pelletizing itafanya kazi kama kawaida katika tukio la tatizo la nishati lisilotarajiwa.

Shuliy plastiki pelletizing mashine kwa ajili ya kuuza

Ili kushughulikia masuala hayo hapo juu, Shuliy, mtengenezaji wa kuaminika, mtaalamu wa maendeleo na uzalishaji wa granulators. Yake HDPE mashine ya kusambaza pelletizing inachukua teknolojia ya hali ya juu na hupitia majaribio makali ili kutoa utendaji bora na utendakazi thabiti.

Iwe ni mashine ya kutengeneza pelletizing ya HDPE au mashine ya kusaga kwa vifaa vingine, Shuliy inaweza kutoa masuluhisho ya hali ya juu ili kuepukana na matatizo yaliyo hapo juu na kuhakikisha ufanisi wa uzalishaji na ubora wa bidhaa. Karibu uwasiliane nasi wakati wowote ili kupata bei ya chembechembe za plastiki, vigezo na maelezo mengine ya mashine.