If you are searching for a turnkey automated line for dry ice blocks, suitable for scaled supply or in-house support, the dry ice blocks production Line converts liquid CO2 into standardized dry ice blocks with balanced capacity, energy use, and product consistency.

The dry ice manufacturing plant is a complete and efficient system designed to produce high-density dry ice blocks through a continuous process that includes pelletizing, block pressing, and final packaging. This production setup is suitable for users who require stable output, customizable block sizes, and reliable performance for industrial cleaning, cold chain logistics, and refrigeration applications.

Why Choose a Dry Ice Blocks Production Line?

Choosing a complete dry ice block production line, rather than individual machines, provides several major advantages:

- Complete & Highly Automated Workflow — From liquid CO₂ → pellets → blocks → packaging, the entire process is streamlined with minimal labor required.

- High Output & Stable Performance — Suitable for small, medium, or large commercial production capacities.

- Flexible & Customizable Product Specifications — Block shapes and sizes can be customized based on market demand.

- Convenient for Storage, Transportation & Sales — Dry ice blocks have higher density and standard shapes, making them easier to package, stack, and transport.

Detailed Workflow of the Dry Ice Blocks Production Line

1. Dry Ice Pelletizing

The production process begins with a dry ice pelletizer that converts liquid CO₂ into solid dry ice pellets. The pellets typically range from Φ3mm to Φ19mm, depending on the machine type.

Uniform pellets ensure stable quality and are essential for the subsequent block-pressing stage.

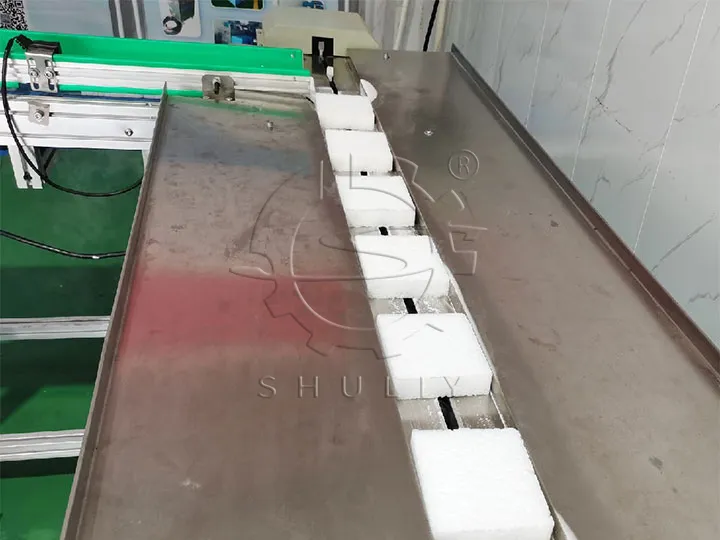

2. Block Pressing (Briquetting)

Next, the dry ice block machine compresses the pellets into high-density dry ice blocks. The block density usually reaches about 1450–1550 kg/m³, and the size can be adjusted by changing the mold.

We can also customise thickness, dimensions and other specifications to meet customer requirements for various applications, such as cold chain logistics, food preservation and stage effects.

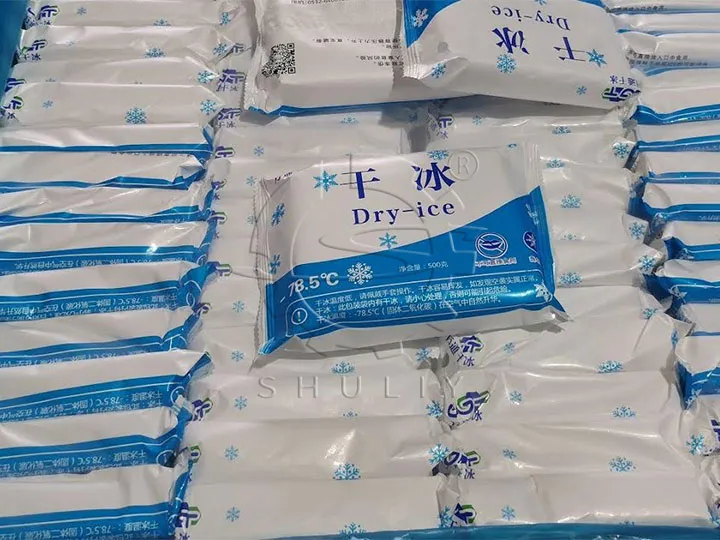

3. Packaging Section

After forming, the blocks enter the packaging stage. The production line can be equipped with a packaging machine to seal the blocks into bags or customized packaging formats.

Proper packaging improves product cleanliness, slows sublimation, and ensures better storage and transport performance.

Advantages of Using a Complete Dry Ice Blocks Production Line

- High Efficiency & Continuous Output: The integrated workflow ensures stable production without frequent interruptions.

- Consistent Block Quality: With controlled pressure and uniform pellet feed, the final blocks achieve ideal density and durability.

- Customizable Block Sizes: Different industries require different block specifications, and the production line fully supports mold customization.

- Reduced Labor & Easy Operation: Automation reduces manual handling while improving safety and operational efficiency.

- Better CO₂ Utilization: Optimized machine design reduces material loss and maximizes conversion rates.

Applications & Value of the Dry Ice Blocks Production Line

Cold Chain Transport / Food & Pharmaceutical Preservation

Dry ice blocks have excellent longevity and high density, making them ideal for cold-chain logistics and temperature-sensitive goods.

Industrial Cleaning / Special Industries

For applications requiring large amounts of dry ice—such as dry ice blasting, low-temperature treatment, stage effects, or scientific experiments—a stable and standardized production line ensures consistent supply.

Commercial Sales / Distribution

Standardized production and packaging help you build reliable distribution channels and expand your customer base.

For businesses aiming to become dependable dry ice suppliers or expand their production scale, investing in a complete dry ice blocks production line ensures higher efficiency, stable quality, and better competitiveness.

How to Choose the Right Production Line Configuration

When selecting a dry ice manufacturing plant, consider the following aspects:

- Production Capacity: Choose suitable pelletizer and block press models according to your daily/monthly output requirements.

- Block Specifications: Select block sizes based on customer needs—small blocks for food or medical use, large blocks for industrial applications or long-distance shipping.

- Automation & Packaging Requirements: If you need to supply wholesale or retail customers, an automatic packaging system ensures better efficiency and product consistency.

- Flexibility & Customization: Opt for machines with replaceable molds and customizable packaging options to adapt to different market demands.

Dry Ice Block Making Machine For Sale

If you are looking for a reliable dry ice block making machine for sale, our dry ice blocks production line offers stable performance, customizable block sizes, and a complete production solution suitable for various industries such as cold-chain logistics, food preservation, industrial cleaning, and medical transportation.

Whether you need a small-capacity unit or a full-scale dry ice blocks production line, we can tailor the right machine to match your output requirements and budget. Contact us today to get detailed specifications, pricing, and a personalized quotation—we are ready to support your dry ice business with professional guidance and high-quality equipment.