私たちのプラスチック洗浄タンクは、プラスチックリサイクルと洗浄のために設計された非常に効率的な設備であり、主にプラスチックの表面から不純物や汚れを取り除くために使用されます。この設備はステンレス鋼で作られており、頑丈で優れた耐腐食性を持っています。PP、PE、PVCの剛性フレークやフィルムの断片など、あらゆる種類の廃プラスチックの洗浄に適しています。

プラスチック洗浄機の紹介

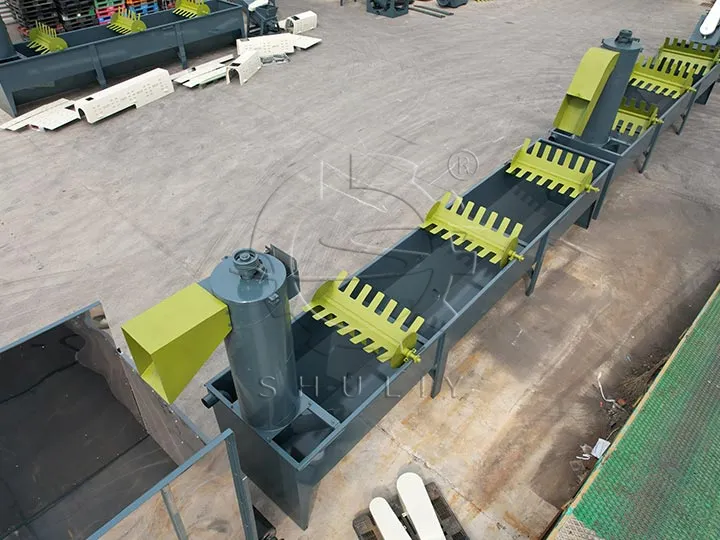

プラスチックチップ洗浄機は、粉砕されたプラスチックを処理するために使用される、プラスチッククラッシャーの後方に配置される主要な装置です。

粉砕されたプラスチックは洗浄タンクに直接落ち、タンク内の複数の攪拌ローラーが材料を効果的に攪拌し、プラスチックの表面に付着した不純物や汚れを取り除き、同時に材料を前方に押し進めることができます。

洗浄タンクの終わりには、通常、垂直脱水機が接続されており、材料を持ち上げて初期乾燥を行うために使用されます。プラスチック洗浄機は、プラスチックの表面から不純物を効率的に除去するだけでなく、脱水機とシームレスに接続されて、洗浄と脱水プロセス全体の効率を向上させます。この組み合わせにより、洗浄されたプラスチックは清潔で不純物がなく、次のリサイクルおよび加工のための高品質な原材料を提供します。

廃プラスチック洗濯機の利点

高品質な素材:洗浄タンクは、長時間錆びず、清掃・メンテナンスが容易な耐腐食性ステンレス鋼で作られています。

高効率攪拌システム:通常、洗浄タンクには3列の攪拌ホイールが装備されており、強力な攪拌によってプラスチック表面の不純物や汚れを効果的に除去します。お客様の生産需要と原料の汚れ具合に応じて、洗浄タンクの長さを延長したり、2基の洗浄タンクを構成したりすることで、洗浄効果を向上させることができます。

柔軟なカスタマイズ:お客様のニーズに合わせて、廃プラスチック洗浄機の長さや攪拌ホイールの数を、具体的な状況に応じて調整し、洗浄効果を最適化することができます。

縦型乾燥機との完璧な組み合わせ:プラスチック廃材洗浄機は、末端で縦型乾燥機に接続されることが多く、洗浄されたプラスチックを持ち上げて初期乾燥を行うことができます。この組み合わせにより、洗浄と脱水プロセスがシームレスに統合され、リサイクルおよび処理プロセス全体の効率が向上します。

プラスチック洗浄タンクの構造

通常、プラスチック洗浄タンクは、高強度で耐腐食性のプラスチック材料で作られており、長期間の安定した運用を確保しています。主な構造には、タンク本体、水の入口、排水口、かくはん装置が含まれます。

タンク本体は深く広いデザインを採用しており、多くのプラスチック製品を収容できるようになっています。また、水の入口と排水口は適切な位置に配置されており、水流の均等な分配と効率的な排出を確保しています。混合装置は通常、歯付きプレートまたは水流攪拌を採用しており、洗浄プロセス中に洗浄液を十分に混合して洗浄効果を向上させるために使用されます。合理的な構造設計により、プラスチック洗浄タンクは表面の汚染物質を効果的に除去し、その後のプラスチックリサイクルプロセスに良好な条件を作り出すことができます。

プラスチックリサイクル洗浄機の作動原理

材料はプラスチックリサイクル洗浄機の前部に投入され、洗浄トグルホイールが回転し、材料を洗浄して前進させます。洗浄プロセス中に、材料の汚れや不純物は下に沈殿します。

数回の洗浄パドル洗浄の後、材料はシンクの端に達し、その後、排出フォークがシンクから出て行きます。シンクの底には3つの排水口があり、廃棄物や不純物が多く蓄積すると、廃棄物や不純物は排水口から排出できます。

プラスチックチップ洗浄機のパラメータ

モデルSL-150は、長さ15〜20メートルの標準的なプラスチックリンスタンクで、6〜10個の回転ホイールが装備されており、各ホイールの間隔は1.5〜2メートルです。100〜500 kg/hの生産量を持つプラスチックペレット化プラントに適しています。当社の最短の洗浄タンクは長さ5メートルで、2つの攪拌ホイールを備え、小規模な生産量に対応します。

ただし、出力が600-1000kg/hレベルに徐々に増加した場合、大規模な生産を効率的に処理できるように、Shuliyは30メートルの長さのプラスチック洗浄タンクへのアップグレードを検討することをお勧めします。より大きな容量の機械を選択することで、高い生産率で効率的なプロセスを維持し、増大する生産ニーズに応えることができます。専門的なソリューションについては、お気軽にお問い合わせください。

プラスチック洗浄タンク工場展示

プラスチック洗浄タンクやその他のプラスチックリサイクル機器に興味がある場合は、いつでも価格や注文の詳細についてご相談ください。

プラスチック洗濯機の価格

高品質で耐久性のあるプラスチックリンスタンクを、リーズナブルで競争力のある価格で提供しています。当社のプラスチック洗浄機は、安定性と効率を確保するために、高度な製造技術で設計されています。設備のアップグレードや新しいプラスチックペレット化プラントの設立が必要な場合でも、当社のプラスチックフィルム洗浄機がお応えします。詳細なリンスタンク価格情報や、お客様に最適なソリューションのカスタマイズについては、お気軽にお問い合わせください。