プラスチックペレット製造機によって生産されるリサイクルペレットは、プラスチック製品の原材料としてプラスチック加工において重要な役割を果たします。しかし、プラスチックペレットの品質はグレードによって異なり、最終製品の品質や性能に影響を与えます。この記事では、プラスチックペレットの良さを評価するためのいくつかの基準について詳しく説明し、プラスチックペレットの品質を向上させる方法を紹介します。

プラスチックペレット製造機によって生産されるペレットのグレードの基準

粒子サイズの一貫性

プラスチックペレットの粒子サイズは、その品質を評価するために使用される最初の基準の一つです。プラスチックペレット製造機によって生産されたリサイクルペレットは、プラスチック加工中に一貫した特性が得られるように、均一なサイズと形状である必要があり、これにより製品の変動を減少させることができます。

熱安定性

プラスチック製品は温度変化や紫外線にさらされることが多いため、プラスチックペレットの熱安定性と耐候性は、その品質を評価する際の重要な基準の一つです。プラスチックペレット製造機によって生産された高品質のプラスチックペレットは、さまざまな環境条件下で最終製品が性能を維持できるように、優れた熱安定性と耐候性を持っている必要があります。

純度

プラスチックペレットの純度は、プラスチックペレット製造機の品質を測る重要なパラメータです。不純物や不純な物質は、プラスチック製品の強度、耐久性、外観を低下させる可能性があります。品質の高いプラスチックペレットは、最終製品の品質を確保するために、可能な不純物や不純な物質を取り除く厳格な精製プロセスを経る必要があります。

プラスチックペレットの品質を向上させる方法

生産プロセスの最適化

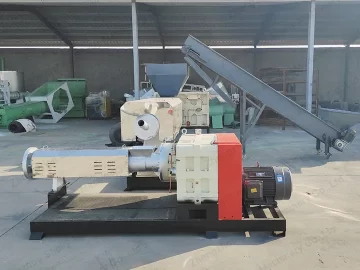

プラスチックペレットの品質は、生産プロセスの最適化によって改善できます。重要なステップの一つは、プラスチックペレット製造機の選択と調整です。適切なプラスチックペレット製造機は、均一なペレットサイズと形状を保証します。さらに、適切な溶融温度と圧力もペレットの品質と性能に影響を与える可能性があります。

厳格な品質管理

厳格な品質管理システムを確立することは、プラスチックペレットの品質を向上させるためのもう一つの重要な方法です。生産プロセス中に物理的特性、組成、融解指数などの重要なパラメータを監視することにより、潜在的な問題を特定し、タイムリーに解決することで、一貫した安定したペレット品質を確保できます。

原材料の選定と取り扱い

プラスチックペレット製造機が生産するプラスチックペレットの品質は、使用される原材料と直接関係しています。高品質の原材料を選ぶことで、ペレットの性能と安定性を効果的に向上させることができます。高品質の原材料は、最終製品の品質を向上させるだけでなく、プラスチックペレット製造機の寿命も延ばします。