シュリィは、著名なプラスチックペレット化ラインの製造業者であり、最近インドネシアのプラスチックリサイクル工場と提携し、新しいプラスチック洗浄ペレット化ラインを供給しました。この記事では、この契約の詳細について説明します。

インドネシアの顧客の背景

このインドネシアの会社とその子会社は、廃棄LDPEフィルムを高品質のリサイクルプラスチックペレットに変換することを専門とした3つのプラスチック洗浄ペレット化ラインを運営しています。増加するプラスチック廃棄物に直面し、彼らは生産効率を改善し、コストを削減し、より環境に優しい製品を提供する必要がありました。

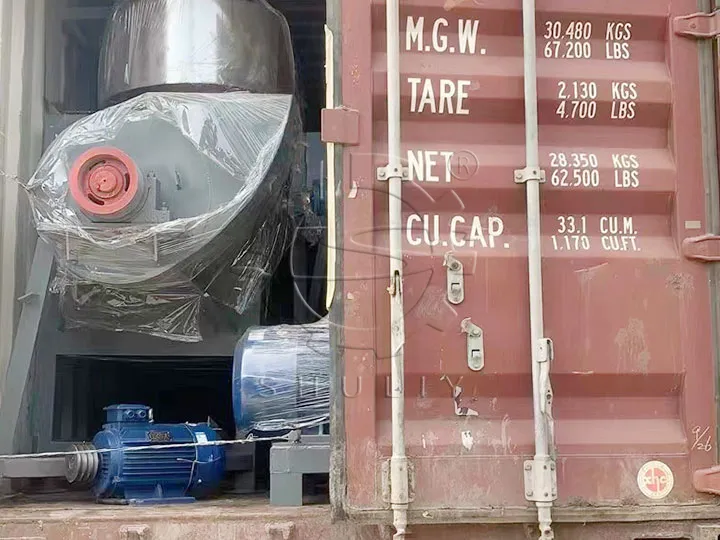

この目標を達成するために、彼らは広範な市場調査を行い、プラスチックの洗浄およびリサイクル設備の製造に優れた評判を持つShuliyという会社を選びました。顧客はShuliyからプラスチックフィルム洗浄機、横型乾燥機、パイプ乾燥機を購入し、これらは効率的なリサイクルと再利用を達成するための重要なツールとなりました。

プラスチックフィルム洗浄リサイクルラインのパラメータ

| アイテム | 仕様 |

| プラスチック洗浄タンク | スクリューローダーと垂直リフター付き 寸法: L5m, W1.2m, H1.3m 厚さ: 3mm 材料: 炭素鋼 底部ねじ刃の厚さ: 6mm 主電力: 5kw 洗浄タンクのグラップル:1.5kw スクリューリフター:3kw 垂直リフター:7.5kw |

| プラスチック乾燥機 | 長さ:3000mm 幅:850mm 出力: 30kw 1500RPM メッシュ素材: 304ステンレス鋼 |

| パイプドライヤー | パイプ直径: 219mm パイプの長さ:20m パイプの厚さ:2mm モーター出力:15kw 加熱粉:30kw 材料:ステンレス鋼201 |

Shuliyプラスチック洗浄ペレット化ラインを選ぶ理由

顧客は明らかな理由から、さまざまな供給者の中からShuliyのプラスチック洗浄ペレット化ラインを選びました。Shuliyは業界でその優れた品質と性能で知られており、特にプラスチックフィルムを扱う際に顧客が必要とするものです。

Shuliyのプラスチック洗浄機は、汚れや不純物を効率的に除去する先進的な洗浄技術を利用しており、原材料の高品質な洗浄を保証します。さらに、水平乾燥機とパイプ乾燥機を備えたプラスチック洗浄ペレット化ラインは、LDPEフィルム材料を迅速に乾燥させ、エネルギー消費を削減し、生産効率を向上させます。

シュリの製品の利点は大きい

プラスチック洗浄ペレット化ラインが稼働し始めると、顧客はすぐに大きな経済的利益を実感しました。まず、Shuliyの設備が原材料を効率的に洗浄・乾燥するため、顧客の生産ラインはより安定して稼働し、ダウンタイムが減少し、生産性が向上しました。

第二に、ラインによって処理されたクリーンなLDPEフィルムチップの品質が向上したため、顧客は高品質のリサイクルプラスチックペレットを生産できるようになり、高品質のリサイクル材料に対する市場の需要を満たし、より高い販売価値を提供しました。さらに、エネルギー消費の削減も生産コストを低下させ、収益性を向上させるのに役立ちました。