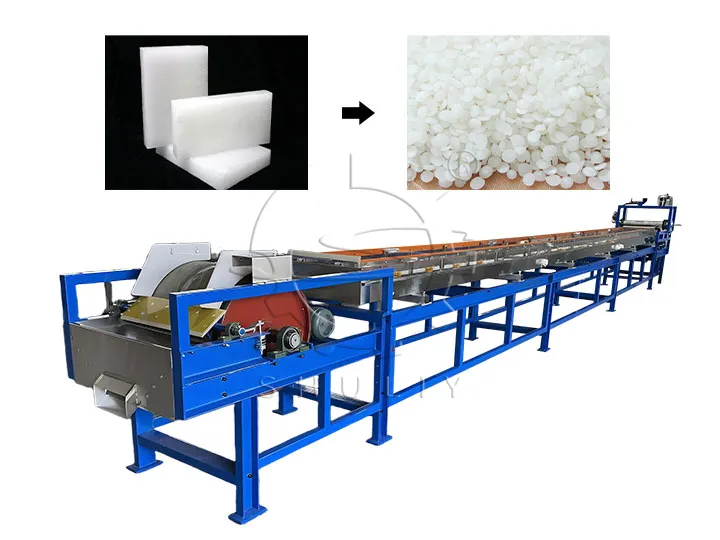

パラフィンワックスパスティレーターは、溶融したパラフィンやその他のホットメルト材料を、連続冷却と成形工程を通じて均一で粉塵のない粒状に変換する工業用機械です。キャンドル、化粧品、香りブースタービーズ、または食品包装や工業用途の材料を製造している場合でも、当社のワックスペレット化機は効率的で安定した生産ソリューションを提供し、液体を簡単に固体粒に変換します。

ワックス粒化ラインの基本動作原理

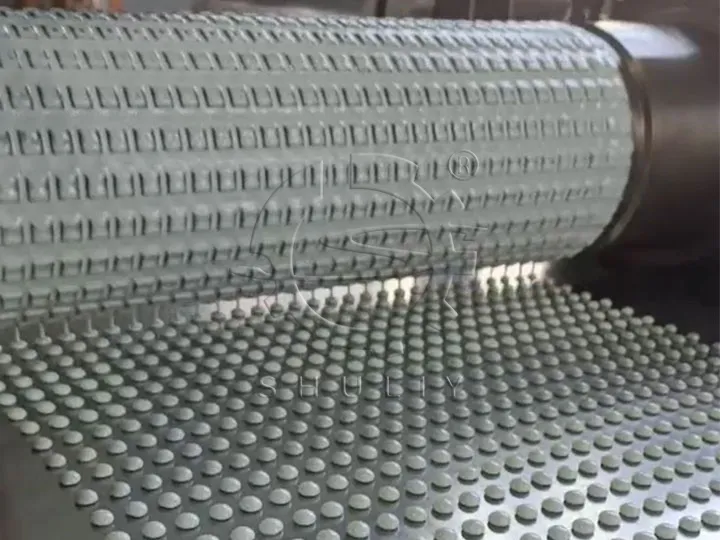

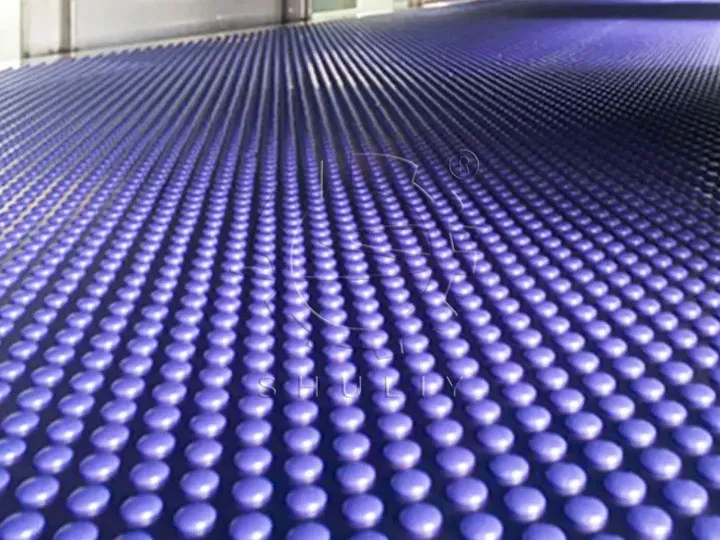

パラフィンワックスパスティレーターの作業フローは正確かつ効率的です。まず、原料を混合・溶解タンクで加熱して溶融状態にします。次に、加熱されたパイプラインを通じて溶融液をパスティレーターのドロッパーに一定速度で供給します。ドロッパーは均一な液滴を冷却鋼ベルトに落下させます。鋼ベルトの下には連続水噴霧システムがあり、ベルトの優れた熱伝導性を利用して材料を迅速に冷却・固化します。最後に、鋼ベルトの端で固化した半球状の粒をスクレーパーで簡単に取り除き、粒化工程を完了します。

完全なワックス粒化ライン構成

| コア機器 | 機能説明 |

| 混合・溶解タンク | 原料の加熱、溶解、混合に使用。必要に応じて着色剤や機能性添加剤をこの段階で加え、顧客のニーズに合わせたカスタマイズ粒を製造します。 |

| 材料ポンプ&熱油ヒーター | 材料ポンプは溶融材料の安定した流れを確保し、熱油ヒーターはパイプラインの温度を維持し、輸送中の材料の固化を効果的に防ぎます。 |

| パスティレーター本体 | 液体材料を均一な粒に変換するコア成形装置。 |

| 冷却循環システム | 水ポンプ、水槽、チラーで構成されるこのシステムは、スプレーノズルを通じて鋼ベルトの裏側を冷却し、粒の迅速な固化を確保します。チラーを装備することで冷却水のリサイクルが可能となり、効率と出力が向上します。 |

適用原料および完成品

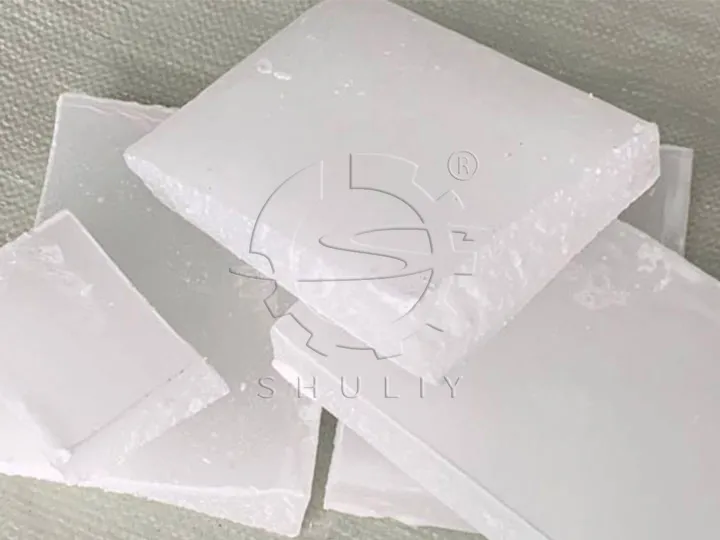

このパラフィンワックスパスティレーターは、優れた材料適応性を備えています。理論的には、50°Cから250°Cの溶点を持ち、加熱によって液体に変わり、冷却によって再び固体に固化できる材料なら何でも粒化可能です。一般的な原料には、パラフィンワックス、ロジン、各種樹脂などがあります。

当社の粒化装置を使用すれば、これらの原料を効率的に均一な粒に加工でき、多用途に利用できます。最終製品の用途は次のとおりです:

- 香りブースタービーズ

- パラフィン粒(キャンドル作りなど用)

- 鋳造用ワックス

- 脱毛ワックス

当社のパラフィンワックスパスティレーターの利点と特徴

- 幅広い用途: 溶点50°Cから250°Cの材料に適しており、冷却時に固化するもの。例としてパラフィンワックス、ロジン、各種樹脂、鋳造用ワックス、脱毛ワックスなどがあります。

- 均一な仕上がりの粒: 出力される粒は半球状で、形状が均一で、サイズも一定(通常4-8mmに調整可能)。粉塵もなく、次工程の計量、輸送、保管が容易です。

- 効率的で安定した生産: 高度な自動化と安定した運転を実現した連続生産設計。周波数制御のドロッパーと鋼ベルトの速度を調整することで、出力と粒径を容易に制御でき、さまざまな生産規模に対応可能です。

- カスタマイズ可能な生産: 異なる着色剤は、香りブースタービーズや彩色キャンドルなど多様な製品の市場需要に応じて、プロセスの開始時に混合タンクに簡単に追加できます。

ワックスパスティレーターの技術仕様

小規模から大規模な工業生産まで対応できるさまざまなモデルのパラフィンワックスパスティレーターを提供しています。

| モデル | 機械幅 | 機械の長さ | 完成品サイズ | パラフィンの容量 |

| SL-W40 | 400mm | 7m | 4-8mm(調整可能) | 50-100kg/h |

| SL-W60 | 600mm | 12m | 4-8mm(調整可能) | 150-200kg/h |

| SL-W100 | 1000mm | 14m | 4-8mm(調整可能) | 300-350kg/h |

| SL-W120 | 1200mm | 15m | 4-8mm(調整可能) | 400kg/h |

| SL-W150 | 1500mm | 23m | 4-8mm(調整可能) | 400kg/h |

注意:電圧やモーター出力などの詳細パラメータは、顧客の具体的な要件に応じて設定可能です。

優れた性能、高い安定性、幅広い適用性を備えた当社のパラフィンワックスパスティレーターは、化学、日用品、新素材など多くの産業で理想的な選択肢となっています。信頼できる粒化ソリューションをお探しの場合は、詳細情報と見積もりについてお気軽にお問い合わせください。