Mesin ekstruder pelet plastik adalah mesin yang mengubah limbah plastik atau bahan plastik mentah menjadi pelet plastik melalui proses peleburan, ekstrusi, pemotongan, dan proses lainnya. Namun, dalam produksi aktual, terkadang timbul masalah perbedaan warna, yaitu warna pelet plastik tidak seragam.

Perbedaan warna tidak hanya memengaruhi kualitas butiran plastik tetapi juga penampilan dan kinerja produk selanjutnya. Dalam artikel ini, kita akan membahas secara mendalam alasan perbedaan warna dalam produksi mesin ekstruder pelet plastik dan solusinya.

Kualitas bahan baku plastik yang tidak konsisten

Keberagaman sumber bahan baku

Bahan baku plastik sering kali berasal dari beberapa pemasok atau sumber daur ulang, dan komposisi plastik dari setiap sumber dapat bervariasi, yang mengakibatkan perbedaan warna pada plastik.

Rasio pencampuran yang tidak tepat

Selama proses regenerasi mesin ekstruder pelet plastik, mencampur sumber dan jenis plastik yang berbeda dengan cara yang tidak wajar dapat menyebabkan warna yang tidak merata dan perbedaan warna.

Solusi

- Pilih pemasok bahan baku yang stabil dan bangun hubungan kerjasama jangka panjang yang stabil untuk memastikan stabilitas kualitas bahan baku.

- Kontrol ketat rasio dan proporsi bahan baku untuk menghindari pencampuran yang berlebihan. Cobalah untuk menjaga satu sumber bahan baku plastik yang digunakan dalam mesin ekstruder pelet plastik.

Pengendalian suhu yang tidak tepat pada mesin ekstruder pelet plastik

Suhu leleh yang tidak stabil

Dalam proses produksi mesin ekstruder pelet plastik, ketidakstabilan suhu leleh akan menyebabkan ketidakkonsistenan warna lelehan plastik dan perbedaan warna.

Suhu pendinginan yang tidak merata

Pendinginan adalah langkah penting dalam proses mesin ekstruder pelet plastik, jika pendinginan tidak merata, itu akan menyebabkan suhu yang tidak konsisten di permukaan pelet, sehingga menghasilkan perbedaan warna.

Solusi

- Pemeliharaan dan perbaikan rutin mesin peletisasi plastik daur ulang untuk memastikan stabilitas sistem pengendalian suhu.

- Optimalkan desain sistem pendingin untuk memastikan efek pendinginan yang merata, untuk menghindari perbedaan suhu partikel.

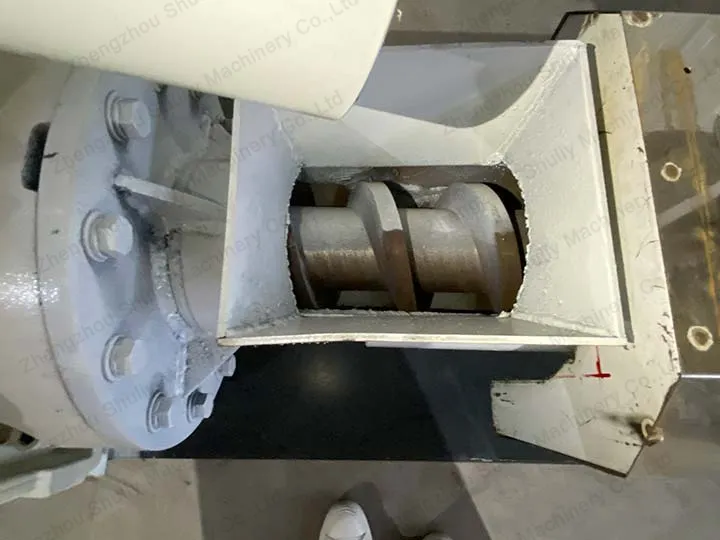

Desain sekrup yang tidak masuk akal

Ketidaksesuaian struktur sekrup

Mesin pelebur pelet plastik sekrup adalah komponen kunci untuk melebur dan mengekstrusi plastik, jika struktur sekrup tidak cocok, mudah menyebabkan aliran plastik cair yang tidak merata, sehingga menimbulkan perbedaan warna.

Kontaminasi residu

Akumulasi residu di dalam sekrup dapat menyebabkan pencampuran plastik dengan warna yang berbeda, yang mengakibatkan perbedaan warna.

Solusi

- Sesuai dengan jenis dan karakteristik plastik yang berbeda, pilih struktur sekrup yang sesuai untuk memastikan aliran lelehan plastik yang merata.

- Bersihkan dan rawat sekrup secara teratur untuk menghindari penumpukan residu.