Our plastic rinsing tank is a highly efficient equipment designed for plastic recycling and washing, which is mainly used to remove impurities and dirt from the surface of plastics. The equipment is made of stainless steel, which is robust and has excellent corrosion resistance. It is suitable for cleaning all kinds of waste plastics, including all kinds of PP PE PVC rigid flakes or film fragments.

Introduction of Plastic Washing Machine

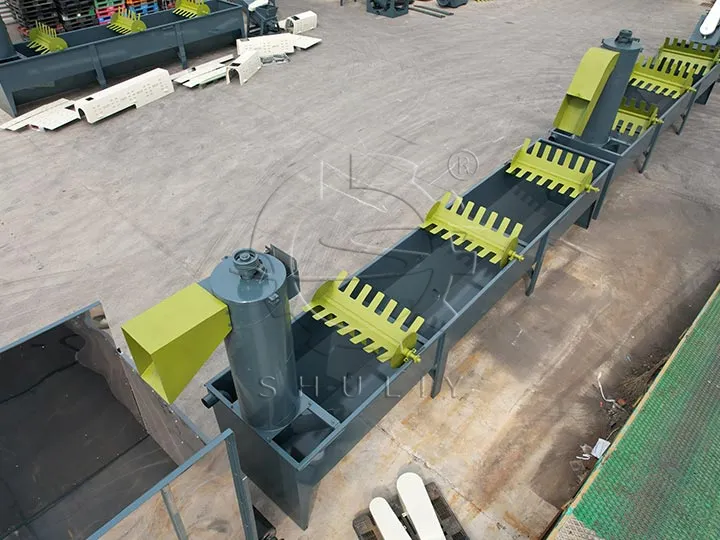

The plastic chips washing machine is a key piece of equipment located behind the broyeur de plastique, which is used to process the crushed plastic.

The crushed plastic falls directly into the washing tank, and the multiple stirring rollers in the tank can effectively stir the material, clean off the impurities and dirt on the surface of the plastic, and at the same time force the material to move forward.

At the end of the washing tank, a vertical dewatering machine is usually connected, which is used to lift the material out and carry out preliminary drying. The plastic washing machine not only efficiently removes contaminants from the surface of the plastic, but also seamlessly connects to the dewatering machine to improve the efficiency of the entire washing and dewatering process. This combination ensures that the washed plastic is clean and free of contaminants, providing high-quality raw material for subsequent recycling and processing.

Advantages of Waste Plastic Washing Machine

High-quality material: The cleaning tank is made of corrosion-resistant, stainless steel, which ensures that it will not rust for a long time and is easy to clean and maintain.

High-efficiency agitation system: A washing tank is usually equipped with three rows of agitator wheels, which effectively remove impurities and dirt from the plastic surface through powerful agitation. According to the customer’s production demand and the degree of dirty raw materials, we can extend the length of the washing tank or configure two cleaning tanks to improve the cleaning effect.

Personnalisation flexible: To meet the needs of different customers, the length of the waste plastic washing machine and the number of agitator wheels can be adjusted according to the specific situation, to optimize the cleaning effect.

A perfect match for vertical dryers: The plastic waste washing machines are often connected to vertical dryers at the end, which can lift out the washed plastics and carry out the initial drying. With this combination, the washing and dewatering process is seamlessly integrated, increasing the efficiency of the entire recycling and disposal process.

Structure of Plastic Washing Tank

Usually, plastic rinsing tanks are made of high-strength, corrosion-resistant plastic materials to ensure long-term stable operation. Its main structure includes the tank body, water inlet, drain, and agitation device.

Le corps du réservoir adopte une conception profonde et large pour accueillir un grand nombre de produits en plastique, tandis que l'entrée et le drain d'eau sont situés à des positions appropriées pour assurer une répartition uniforme du débit d'eau et une évacuation efficace. Le dispositif de mélange adopte généralement une plaque dentée ou une agitation à débit d'eau, qui est utilisée pour mélanger suffisamment le liquide de nettoyage pendant le processus de nettoyage afin d'améliorer l'effet de nettoyage. Grâce à une conception structurelle raisonnable, le réservoir de rinçage en plastique peut éliminer efficacement les polluants de surface et créer de bonnes conditions pour le processus ultérieur de recyclage du plastique.

Working Principle of Plastic Recycling Washing Machine

Le matériau est placé à l'avant de la machine à laver de recyclage du plastique, la roue à bascule de rinçage tourne et entraîne le matériau à rincer et à avancer, et les déchets et impuretés présents sur le matériau sont précipités vers le bas pendant le processus de rinçage.

Après plusieurs rinçages par roue à aubes, le matériau atteint l'extrémité de l'évier, puis la fourche de décharge sort de l'évier. Le fond de l'évier dispose de trois ports d'égout. Lorsque les déblais et les impuretés s'accumulent davantage, les déblais et les impuretés peuvent être évacués par le port d'égout.

Parameters of Plastic Chips Washing Machine

Model SL-150 is a standard model plastic rinsing tank designed for lengths between 15 and 20 meters, equipped with 6-10 rotating wheels with a distance between each two wheels of between 1.5 and 2 meters. It is suitable for plastic pelletizing plants with outputs in the range of 100-500 kg/h. Our shortest washing tank is 5 meters with two agitator wheels for smaller outputs.

However, once your output gradually increases to the 600-1000kg/h level, to ensure that you can efficiently handle larger production runs, Shuliy recommends that you consider upgrading to a longer plastic rinsing tank, such as a thirty-metre long model. By choosing a larger capacity machine, you can ensure that you can maintain an efficient process at high production rates and meet your growing production needs. You can also feel free to contact us for specialized solutions.

Plastic Rinsing Tank Factory Display

Si vous êtes intéressé par le réservoir de rinçage en plastique ou par tout autre équipement de recyclage du plastique, veuillez nous contacter à tout moment pour discuter des prix et des détails de commande.

Plastic Washing Machine Price

We offer high-quality and durable plastic rinsing tanks at reasonable and competitive prices. Our plastic washing machines are well-designed with advanced manufacturing technology to ensure stability and efficiency. Whether you need to upgrade your equipment or set up a new usine de granulation de plastique, our plastic film washing machines will meet your needs. Please feel free to contact us, we will provide you with detailed information about the rinsing tank price and customize the most suitable solution for you.